Ash Handling Systems(Bottom Ash, Fly Ash

An ash handling system collects and transports the bottom ash and the fly ash generated in coal fired thermal power plants to an ash pond or ash storage silo. There are two types of bottom ash handling system; wet handling system cooling by water and dry handling system cooling by air. The fly ash is used as a raw material for cement and an additive mixture for concrete while the bottom ash is recycled into bricks and aggregates as construction materials. Halla’s ash handling systems minimize environmental pollution and maximize the economical benefits from the extended recycling

Projects

| No. | Project Name | Client | Size/specification |

|---|---|---|---|

| 1 | Bottom ash system for the Yeongheung Thermal Power Plant Unit 3, Unit 4 | Korea South-East Power Co.,Ltd. | 870MW x 2 |

| 2 | Bottom ash system for the Dangjin Thermal Power Plant Unit 9, Unit 10 | Daelim Industrial Co.,Ltd. | 1,000MW x 2 |

| 3 | Bottom ash system for the Yeongheung Thermal Power Plant Unit 5, Unit 6 | Korea South-East Power Co.,Ltd. | 870MW x 2 |

| 4 | Bottom ash system for the Taean Thermal Power Plant Unit 9, Unit 10 | Korea Western Power Co.,Ltd. | 1,000MW x 2 |

| 5 | Fly ash system for the Yeongheung Thermal Power Plant Unit 1, Unit 2 | Korea South-East Power Co.,Ltd. | 800MW x 2 |

| 6 | Fly ash system for the Taean Thermal Power Plant Unit 7, Unit 8 | Korea Western Power Co.,Ltd. | 500MW x 2 |

| 7 | Fly ash system for the Dangjin Thermal Power Plant Unit 9, Unit 10 | Korea East-West Power Co.,Ltd. | 1,000MW x 2 |

| 8 | Ash refinery system for the Taean Thermal Power Plant Unit 5 ~ Unit 8 | Korea Western Power Co.,Ltd. | 500MW x 4 |

Coal handling systems

Main systems are composed of ship unloader or rotary car dumper, thaw shed, conveying system which is responsible for first loading and unloading, and stacker & reclaimer which is responsible for stacking and reclaiming coals. Halla is producing and supplying coal handling systems based on its high technology and abundant experience.

Projects

| No. | Project Name | Client | Size/specification |

|---|---|---|---|

| 1 | Coal handling system for the Taean Thermal Power Plant | Korea Western Power Co.,Ltd. | 600 ton/hr, 800 ton/hr |

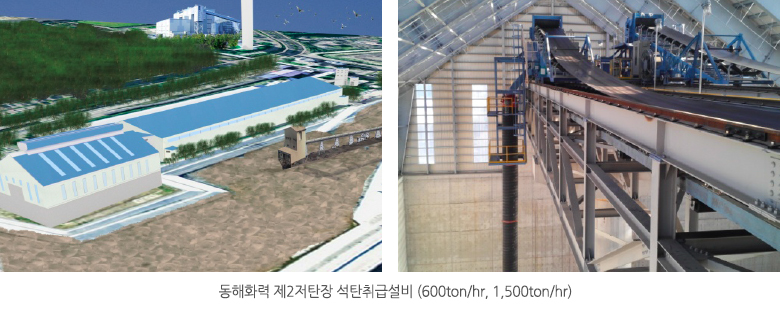

| 2 | Coal handling system of Donghai thermal power No. 2 coal yard | Korea East-West Power Co.,Ltd. | 600 ton/hr, 1,500 ton/hr Indoor type shed : 50,000 ton |

| 3 | Coal handling system of Goseonghai thermal power unit 1, unit 2 | SK Engineering & Construction Co.,Ltd | 4,800 ton/hr |

Gypsum and Limestone Handling System

Gypsum and limestone handling system are composed of limestone unloading unit, conveying conveyor, limestone storage unit, limestone slurry preparation building of limestone daily storage tank, and system which transfer gypsum from the gypsum dehydrated copper to the gypsum shed. Halla is producing and supplying reliable gypsum and limestone handling system through its rich experience

Projects

| No. | Project Name | Client | Size/specification |

|---|---|---|---|

| 1 | Desulfurization system for the Boryeong power unit 7, unit 8(Gypsum and limestone handling system) | Korea Midland Power Co.,Ltd. | 200 ton/hr |

| 2 | Limestone of cargo handling system on land of Taean power unit 1~ 8 | Korea Western Power Co.,Ltd. | 120 ton/hr |

| 3 | Gypsum and limestone handling system of Goseonghai thermal power unit 1, unit 2 | SK Engineering & Construction Co.,Ltd | 350 ton/hr |

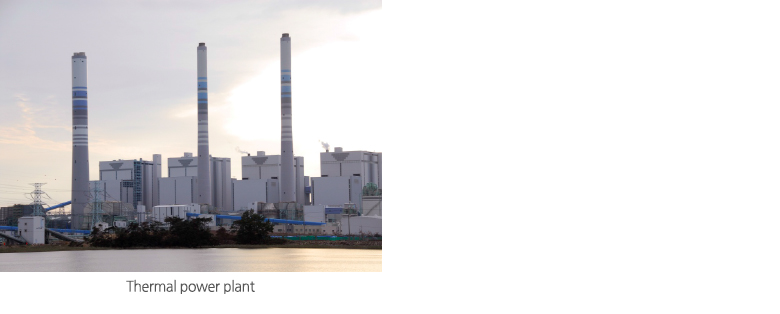

Thermal power plant

In response to the rapidly increasing global demand for power generation Halla provides high quality and competitive power generation plants based on accumulated technology and abundant experience in the field of comprehensive plant.

Halla’s ability of technology and business management provides high quality services in all fields of EPC ranging from design, procurement, construction, and commissioning.

Cement Plants

Halla had successfully completed and supplied many large-scale cement plants and production facilities such as Lafarge-Halla Cement and Hyundai Cement project in Korea, SPCC in Saudi Arabia, and NSCI in Malaysia, etc. We have been also engaged in maintenance, renovation and rehabilitation of major cement plants at home and abroad to improve the plants productivity and efficiency.

Projects

| No. | Project Name | Client | Size/specification |

|---|---|---|---|

| 1 | Okgye No.1 Halla Cement | Halla Cement | 3,600 ton/day |

| 2 | Okgye No.2 - 2~4Halla Cement | Halla Cement | 5,500 ton/day x 3Lines |

| 3 | Saudi Arabia - Bisha Cement | SPCC | 3,800 ton/day |

| 4 | Malaysia Negeri Sembilan Cement | CIMA | 3,600 ton/day |