Stoker

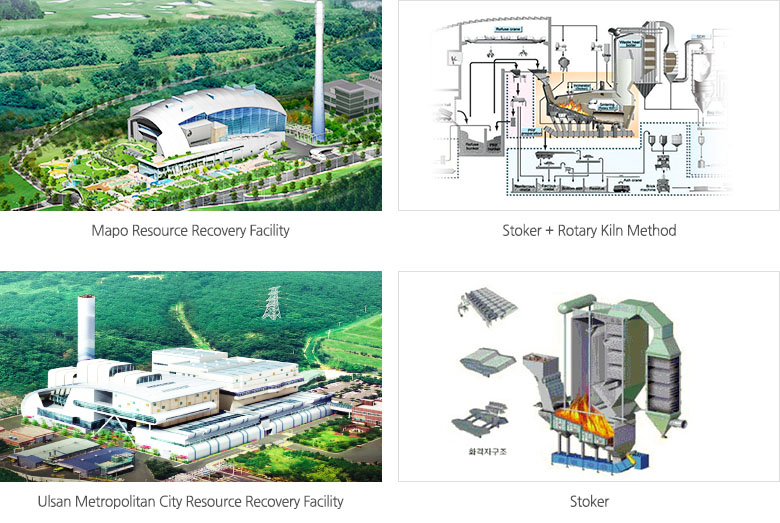

Stoker incinerator is a technology that incinerate waste without pre-processing to produce energy and minimize pollutants.

Halla¡¯s waste incinerator contributes to renewable power generating, too. Steam generated utilizing the waste heat from the incinerator is being sold for district heating and/or utilized to generate electric power by operating the steam turbine generator. we have advanced technology that maximizes energy production and minimizes the generation of pollutants by application of various stoker with optimizing incineration efficiency(water-cooled incinerator, air-cooled incinerator, vibration type incinerator) according to characteristics of waste.

Pyrolysis, Gasification & Melting Incinerator (fluidized bed type)

In the fluidized bed type pyrolysis, gasification & melting incinerator, the waste is partly combusted by fluidized material and dissolved by the heat of combustion. Accordingly, the generated carbide can be melted in the Swirling - Flow Melting Furnace by the heat of gas combustion and formed as environmentally stable slag.

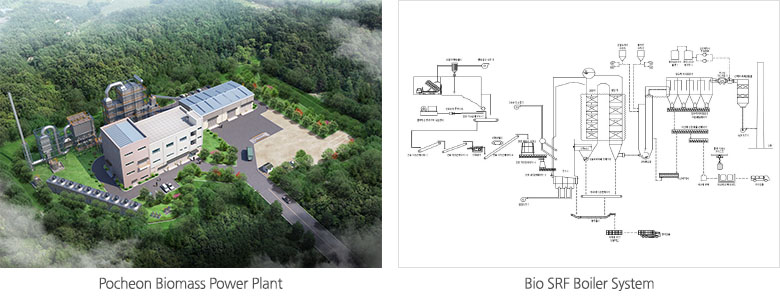

Biomass Boiler

SRF is classified as SRF based on non-industrial waste and Bio-SRF based on waste wood and wood by-products and it has technology and experience that is optimized for the construction of biomass power plant applying stoker or fluid-type SRF boiler according to scale and characteristic of materials

MBT (Mechanical Biological Treatment)

With MBT (Mechanical Biological Treatment) technology, the waste is separated mechanically before simple incineration or being taken to a landfill to collect the recyclable materials and to produce the RDF. This maximizes the amount of waste that can be turned into energy and minimizes the amount of waste that must incinerated or taken to a landfill. The produced RDF can be used as an alternative fuel in cement production and power generation plants, and the produced biogas can be used for power generation.

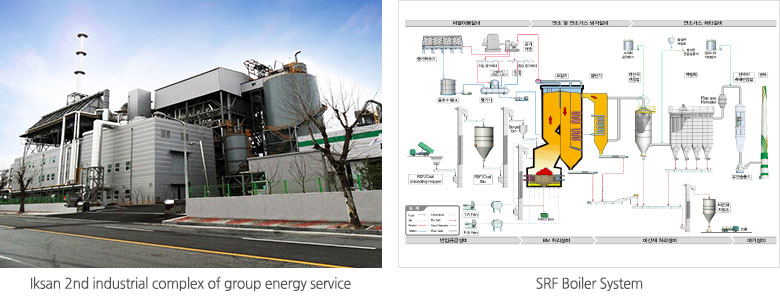

Group energy(Solid Refuse Fuel)

SRF(Solid Refuse Fuel) is a solid fuel made by processing combustible component and removing from dry, crushing, sorting of incombustible matters such as moisture, metals and glass contained in wastes. Utilizes fluidized bed boiler technology designed for combustion of SRF. Because fluidized bed boiler is well mixed in the bed and full combustion is possible at relatively low temperatures and excess air ratio, and at fuel that contains a lot of moisture is also excellent adaptation. Also, the fludidized bed method has advantage of being able to suppress emission environmental contamination without a separate process. The steam produced by burning the SRF is generated electricity by using a steam turbine generator and it burns SRF from here and increase power generation efficiency to supplies high-temperature and high-pressure steam at industrial complex. Power generation utilizing SRF is eco-friendly energy recovery method that recovers energy from waste.it shall produce electricity as alternative fuel and produced biogas in cattle.

Projects

| No. | Project Name | Client | Size/specification |

|---|---|---|---|

| 1 | Mapo municipal solid waste incineration plant | Seoul City | 250ton/day¡¿ 3 unit |

| 2 | Changwon City garbage incineration plant | Changwon City | 200ton/day¡¿ 2 unit |

| 3 | Seongnam pangyo clean tower | Korea Land Corporation | 45ton/day ¡¿ 2 unit |

| 4 | Ulsan Metropolitan City municipal solid waste incineration plant | Ulsan Metropolitan City | 200ton/day ¡¿ 2 unit + 250ton/day ¡¿ 1 unit |

| 5 | Asan incineration plant | Asan City | 200ton/day |

| 6 | Yangyang County municipal solid waste incinerator | Yangyang County | 30ton/day |

| 7 | Mechanical biological treatment facility of Naju household waste for installation | Korea Environment Corporation | 130ton/day |

| 8 | Hangbok City solid waste fuel | Korea Land and Housing Corporation | 130ton/day |

| 9 | Iksan 2nd industrial complex of group energy plant | Iksn Sangong Energy | 9.8MW, 75ton/hr |

Sludge Drying Bed (Fuel)

Sludge generated at sewage water or wastewater treatment plants is a facility that produces fuel by using external heat source such as steam and drying.

The produced fuel is used as auxiliary fuel and supplied to the power plant and the cement plant. Halla Energy & Environment on the basis of our abundant experiences of having designed and installed is supplying optimal facilities suited for characteristics of the sludge itself.

Sludge incineration

Sludge generated at sewage water or wastewater treatment plans is pre-dried for incineration. Dried sludge burns in the incinerator without auxiliary fuel to produce steam and produced steam is supplied as a dry heat source to save energy. Halla Energy & Environment on the basis of our experience of having designed and installed to the largest sludge incinerator in domestic is supplying optimal facilities suited for characteristics of the sludge itself.

Projects

| No. | Project Name | Client | Size/specification |

|---|---|---|---|

| 1 | Gwangju City Sewage Sludge Facility | Gwangju Metropolitan General Construction Office | 110ton/day ¡¿ 3unit |

| 2 | Yangsan City Sewage Sludge Facility | Yangsan City | 60ton/day ¡¿ 2unit |

| 3 | Chungju City Sewage Sludge Facility | Korea Environment Corporation | 60ton/day |

| 4 | Changwon deokdong Sewage Sludge Facility | Changwon City | 200ton/day ¡¿ 1unit |

Biogasification

Two phase anaerobic digestion process for organic wastes recycling technology developed by Halla Energy & Environment can be used for biogas production not only through the anaerobic digestion of food waste with high sodium and water content, but also through various biodegradable organic waste like livestock manure, sewage sludge, etc. Sewage sludge, generated from the anaerobic digestion of organic waste is used as high quality compost or liquefied fertilizer and produces biogas as an alternative energy source for boilers and power generation facilities

Composting

Aerobic composting is decomposition of organic matter by using microorganism that oxidize and decompose the material by using oxygen and at the same time, it is a technology to produce a new material in the form of compost that can use decomposition residue as land improvement.

Biogas Refining and High Quality Technology

It is facility to produce high purity biomethane by distilling biogas which is produced at anaerobic digestion facility such as landfill, sewage treatment facility and organic waste recycling facility. Produced high purity biomethane shall be responded positively to alternative energy sources and climate change which is utilized as automotive fuel to replace fossil fuels. it produce biomethane about 14,400N§©/per day and supply fuel to 200 vehicles in a day through the biogas automatic fuel facility of installation and operation at metropolitan landfill site. Basically, we are actively responding to changes in technology for organic waste recycling such as food waste, organic sludge, and waste water and making all efforts to increase penetration of CNG fuel vehicles and renewable energy by using biogas fuel technology.

Projects

| No. | Project Name | Client | Size/specification |

|---|---|---|---|

| 1 | Mapo municipal solid waste incineration plant | Seoul City | 250ton/day¡¿ 3 unit |

| 2 | Changwon City garbage incineration plant | Changwon City | 200ton/day¡¿ 2 unit |

| 3 | Seongnam pangyo clean tower | Korea Land Corporation | 45ton/day ¡¿ 2 unit |

| 4 | Ulsan Metropolitan City municipal solid waste incineration plant | Ulsan Metropolitan City | 200ton/day ¡¿ 2 unit + 250ton/day ¡¿ 1 unit |

| 5 | Asan incineration plant | Asan City | 200ton/day |

| 6 | Yangyang County municipal solid waste incinerator | Yangyang County | 30ton/day |

| 7 | Mechanical biological treatment facility of Naju household waste for installation | Korea Environment Corporation | 130ton/day |

Pneumatic Refuse Collection System

Waste is thrown into a hopper and transported through pipes using air vacuum and pressure to collection areas. Then the waste is separated and crushed or pressed so it can be easily transported to the 2nd stage or final stage treatment facility. This is an environment friendly technology that is excellent for use in downtown areas.

Projects

| No. | Project Name | Client | Size/specification |

|---|---|---|---|

| 1 | Pangyo City Clean Net | Korea Land and Housing Corporation | 47.2ton/day |

| 2 | Namyangju City Byeollae Auto Clean Net | Korea Land and Housing Corporation | 39.69ton/day |

| 3 | Gimpo Hangang New Town Pneumatic Waste Collection System | Korea Land and Housing Corporation | 77.35ton/day |

| 4 | Incheon City Chongna Auto Clean Net | Korea Land and Housing Corporation | 75ton/day |

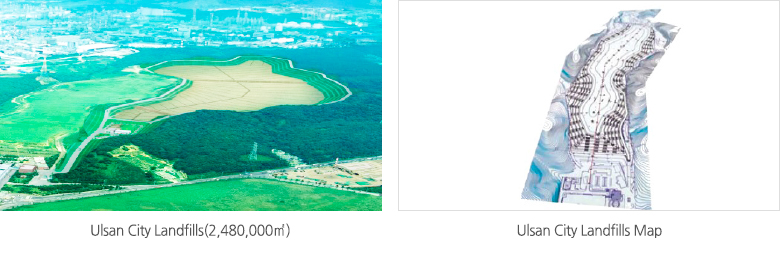

Landfills

We construct sanitary and safe landfills for municipal solid waste and fly ash utilizing the anaerobic cell method, an advanced technology to minimize environmental pollution from secondary pollution substances

Projects

| No. | Project Name | Client | Size/specification |

|---|---|---|---|

| 1 | Ulsan City Landfills | 2,480,000§© |